La Fornace Farm

Montalcino-Siena

La Fornace is a small family-run business of approximately 7 HA.

La Fornace is a small family-run business of approximately 7 HA.

.webp) The Fornace has this particular name because in 1490, it was born as a brick kiln.

The Fornace has this particular name because in 1490, it was born as a brick kiln.

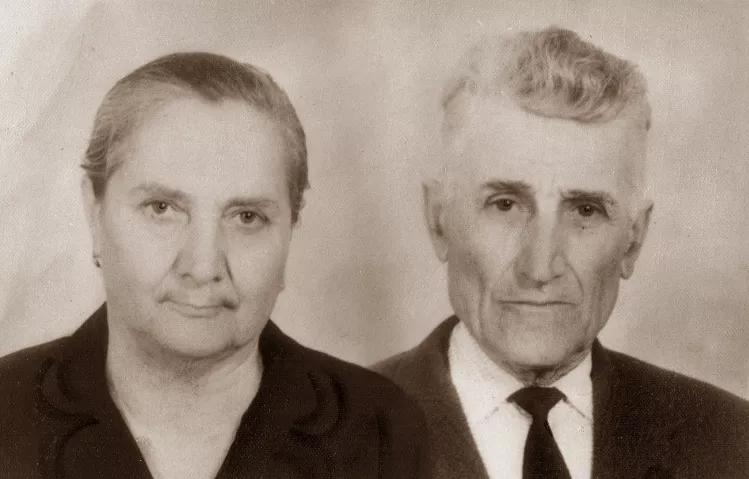

Grandfather Giuseppe purchased the Fornace in 1964 after a life as a sharecropper for the church and many sacrifices. At the beginning there were only 2 HA with a small vineyard of ½ HA. Grandfather Giuseppe came from generations of farmers and producers of wine and oil but as happened in those days, small producers did not bottle their own wine but sold it to larger wineries.

Grandfather Giuseppe purchased the Fornace in 1964 after a life as a sharecropper for the church and many sacrifices. At the beginning there were only 2 HA with a small vineyard of ½ HA. Grandfather Giuseppe came from generations of farmers and producers of wine and oil but as happened in those days, small producers did not bottle their own wine but sold it to larger wineries.

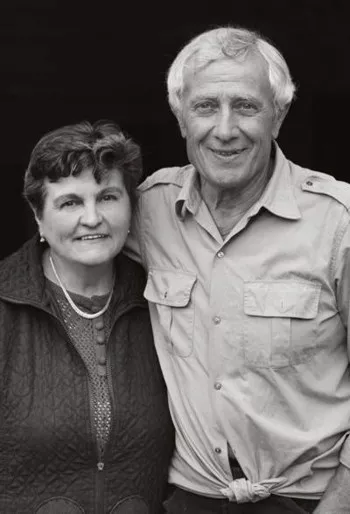

In 1975, father Franco and mother Germana had the opportunity to purchase other land nearby where they planted other vineyards.

In 1975, father Franco and mother Germana had the opportunity to purchase other land nearby where they planted other vineyards.

My parents started bottling with 1000 bottles of wine per type in 1987 with Rosso di Montalcino and in 1988 they started bottling with Brunello di Montalcino. Today we produce around 18,000 bottles in the best years even if the company could produce around 30,000 bottles, but we always prefer to seek the highest quality without compromises.

My parents started bottling with 1000 bottles of wine per type in 1987 with Rosso di Montalcino and in 1988 they started bottling with Brunello di Montalcino. Today we produce around 18,000 bottles in the best years even if the company could produce around 30,000 bottles, but we always prefer to seek the highest quality without compromises.

In 1998 my parents decided it was time to start another adventure so they left me the reins of the company. Fornace follows the rules of nature for its products, trying to limit any external and polluting agent as much as possible and to respect the natural course of the seasons and the passing of time, which is why all the most important work for the production of wine is carried out from the expert hands of our family.

In 1998 my parents decided it was time to start another adventure so they left me the reins of the company. Fornace follows the rules of nature for its products, trying to limit any external and polluting agent as much as possible and to respect the natural course of the seasons and the passing of time, which is why all the most important work for the production of wine is carried out from the expert hands of our family.

The vineyards are located on the north-eastern side of the Montalcino hill at a height of approximately 400 meters and the soil is composed of sandy beaches with the presence of clay. We produce Rosso di Montalcino from the youngest vines (6/16 years) and Brunello di Montalcino from the oldest vines (16/38 years). All the most important processes are rigorously handmade by us as a family.

The vineyards are located on the north-eastern side of the Montalcino hill at a height of approximately 400 meters and the soil is composed of sandy beaches with the presence of clay. We produce Rosso di Montalcino from the youngest vines (6/16 years) and Brunello di Montalcino from the oldest vines (16/38 years). All the most important processes are rigorously handmade by us as a family.

The harvest is rigorously done by hand by qualified people. After an initial selection in the vineyard, the grapes are selected grain by grain on a vibrating sorting table. Only for the harvest we use external specialized workers, this allows us to be able to harvest quickly, and therefore not wait a long time from harvesting to transferring the grapes to the cellar, and at the same time being able to make excellent selections in the vineyard. For each row we make 2 or 3 passes so that we can only harvest the grapes we want. To produce Brunello di Montalcino Riserva we use smaller bunches selected in small areas of our vineyards. To be able to work as easily as possible, the grape harvesters use buckets which, once full, are delicately emptied into a tractor bin, when the latter is full it arrives in the cellar where it is emptied into the destemmer (a machine used to separate the stem from the beans). The beans fall delicately into a sorting table, the table is a vibrating table where the expert hands of trusted people select bean by bean. The selected beans fall into the crusher where they are lightly crushed and after which a pump transfers the must into stainless steel vats.

We have approximately 3 hectares of olive groves composed mainly of Frantoiano, a small percentage of Leccino and other native Tuscan varieties. Our extra virgin olive oil comes only from our olive trees grown and managed entirely by us as a family.

We have approximately 3 hectares of olive groves composed mainly of Frantoiano, a small percentage of Leccino and other native Tuscan varieties. Our extra virgin olive oil comes only from our olive trees grown and managed entirely by us as a family.

The olive harvest is very early, we use manual facilitators to speed up the harvest so that every evening we can take the olives to the latest generation oil mill which is able to extract the oil quickly without stressing it to keep all the organoleptic properties intact. Our extra virgin olive oil is unfiltered, and this helps to enhance its flavor and aroma.

Our cellar is underground to have a constant temperature. The vinification is done in stainless steel vats at a controlled temperature, in the first days cryomaceration at 7°C to preserve the most elegant and delicate aromas, then we proceed with the normal fermentation with indigenous yeasts and with frequent pumping over or punching down. During the fermentation period we carry out up to 3/4 pumping overs per day and 3/4 punching downs per day. While the first is an aggressive system, the second is a soft extraction system. Naturally, each vintage needs to be followed differently and it is very important to taste the must and continuously check the consistency of the skins. Once fermentation is finished we move on to racking which is carried out using a soft press. We do not use the wine from the press to produce bottled wines, but it is used to make table wine together with the second choices of the harvest. The malolactic fermentation in steel and in January the vintages that have now finished aging in wood return to steel to then be bottled and the new vintage begins aging in wood. At this time some barrels are replaced with new barrels. During the refinement period it is very important that the wine is tasted and checked in order to understand its evolution and decide when to move it from one barrel to another.

Our cellar is underground to have a constant temperature. The vinification is done in stainless steel vats at a controlled temperature, in the first days cryomaceration at 7°C to preserve the most elegant and delicate aromas, then we proceed with the normal fermentation with indigenous yeasts and with frequent pumping over or punching down. During the fermentation period we carry out up to 3/4 pumping overs per day and 3/4 punching downs per day. While the first is an aggressive system, the second is a soft extraction system. Naturally, each vintage needs to be followed differently and it is very important to taste the must and continuously check the consistency of the skins. Once fermentation is finished we move on to racking which is carried out using a soft press. We do not use the wine from the press to produce bottled wines, but it is used to make table wine together with the second choices of the harvest. The malolactic fermentation in steel and in January the vintages that have now finished aging in wood return to steel to then be bottled and the new vintage begins aging in wood. At this time some barrels are replaced with new barrels. During the refinement period it is very important that the wine is tasted and checked in order to understand its evolution and decide when to move it from one barrel to another.